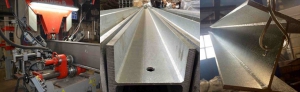

Welded I-Beams

We produce and deliver welded I-beams with the following dimensions:

Н – Height of the I-beam wall, mm – from 132 to 1500

L – Length of the I-beam, mm – from 2000 to 12000

B – I – beam shelf width, mm – from 100 to 800

S – The thickness of the I – beam wall, mm – from 5 to 30

t – The thickness of the shelf of the I – beam, mm – from 6 to 50

The welded I-beam which is made by the welding of steel sheets, is used in construction for the installation of load-bearing structures and is an analogue of a hot-rolled beam.

The main advantages of using a welded I-beam:

– It allows to significantly decrease the weight of the elements of frame metal structures which have an increased safety factor.

— It allows to create cost – effective forms of supports, which in turn reduces the weight of all metal structures.

– Manufacturers of rolled metal do not produce rolled beams larger than 60B. Therefore, when beams are required which rigidity and bearing capacity exceed the capabilities of rolling profiles, then welded I- beams are used.

– Ease of use makes it possible to create buildings of different architectural types;

The production of welded I-beams is carried out on the up-to-date line of automatic equipment, which provides excellent geometry, full welding penetration and perfect appearance of the finished welded I-beam.

Main areas of application of welded I-beams

– frame construction of residential, industrial and agricultural buildings and structures;

– on working platforms, crane beams, floors;

– bridges, overpasses and other steel structures.

Quality management system

The production unit in Sarny supports ISO 9001:2015 quality assurance system. Welding production is certified according ISO 3834-2.

According to the received ISO 3834-2 certificate, we use welding processes 111, 135 and 121. We are certified to work with raw materials which belong to groups 1.1, 1.2 (ISO/TR 15608).

The Factory production control (FPC) system of our production unit is certified according EN 1090 1,2 , EXC 3. We have a right to export CE marked steel structures for EU customers.

The quality control department is headed by the specialist with International Welding Inspector qualification.

Visual and Ultra – sound types of NDT are used during the production process. The control of zinc coating after HDG is provided in accordance with ISO 1461:2009. The production unit has an agreement with an independent ISO certified laboratory, so other types of NDT control are possible on demand from the side of customers.